vacuum bottle test procedure pdf|vacuum bottle integrity testing : exporting in the specifications for in-service testing of vacuum inter-rupters installed in electrical equipment. Testing procedures can be broken into two categories — Visual/Mechanical and Electrical. . 10 de ago. de 2023 · Player Stats Reinildo. Reinildo was born on Jan. 21, 1994. He is currently 29 years old and plays as a Full Back for Atlético de Madrid in Spain. His .

{plog:ftitle_list}

Read the latest Sport news, including Football, UFC, Boxing, .

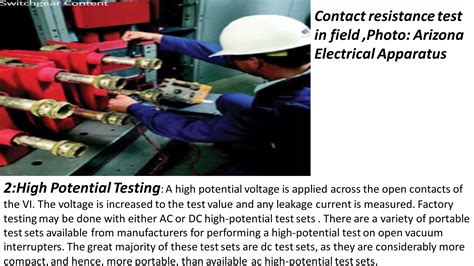

HVI hipots offer far higher current and power ratings, enabling them to test most equipment in a substation. Don’t get caught short with a hipot unable to test bushings, reclosures, hot sticks, etc.in the specifications for in-service testing of vacuum inter-rupters installed in electrical equipment. Testing procedures can be broken into two categories — Visual/Mechanical and Electrical. .The vacuum integrity test set provides a very reliable method of verifying the circuit breaker interrupters are functional after work has been performed. The factory test of a vacuum .Application Overview. When testing most substation apparatus, motors, cables, aerial lifts, etc., the question is: can the item withstand an AC over voltage test without failing? In the case of a .

The VBT-75P S2 is Vanguard's second generation microprocessor-based, portable 75 kV dc vacuum bottle tester. This lightweight, portable tester is designed for testing circuit-breaker .It outlines the necessary test equipment, includes visual inspection steps, and details tests to check insulation resistance, contact resistance, timing of open/close operations, for gas leakage, and high voltage testing of the .

View and Download Vanguard VBT-60 operating instructions manual online. Vacuum Bottle Tester. VBT-60 test equipment pdf manual download. Also for: Vbt-80.Vacuum Bottle Breaker Application and Testing Guide - Free download as PDF File (.pdf), Text File (.txt) or read online for free. vacuum_bottle_breaker_application_and_testing_guide.

adhd and its impact on test taking

View and Download Vanguard Instruments VBT-75P user manual online. VACUUM BOTTLE TESTER. VBT-75P test equipment pdf manual download.Liquid Dielectric & Vacuum Bottle Testing 4 Resistance & Turns Ratio Measurement 5. Voltage Measurement & Frequency Response Analysis 6 Power Factor / C Tan . δ. 7. HV ies 800 SERIES. OC SERIES 2795 / 2796. K 7B T60 2293. VM SERIES 5462. AC HIPOT • • •• Closing the test kit valve and removing the hose from the test cock. As the assembly is drained through the open test cock, the air inlet valve should continue to open. • When water has drained from the assembly, the air inlet must open fully. Record on the test report form the initial opening psid value of the air inlet valve. This guide covers the basic theory and applications for Magnetron Atmospheric Condition testing of vacuum interrupters. Photo: TestGuy. Vacuum interrupters have been used extensively in modern electrical systems to .

BOTTLE LEAK TEST PROCEDURE 👉🏼 The ASTM D5094* is a LEAK Test Method for Bottles, Caps and Containers.00:00 Intro00:25 Scope00:54 Leak Causes01:32 ASTM D509.Export test report in Excel, XML, and PDF format Stand-alone or computer-controlled Automatically detects and tests 67 transformer types deined by ANSI, CEI/IEC and Australian . 75 kVdc vacuum bottle testers 10 kV to 75 kVdc test voltages in 5 kV steps 100, 200, 300 micro-amperes program-mable test current• Submerge test sample in water; apply air to target pressure; hold for pre-determined time • Observe for continuous stream of bubbles. Test (External Vacuum): ASTM D3078 • Submerge test sample in water or other suitable fluid in vacuum chamber • Evacuate chamber to target pressure; hold for pre- determined timeis: can the item withstand an AC over voltage test without failing? In the case of a vacuum bottle, is the vacuum chamber sealed with the vacuum intact or not? Does it hold the test voltage or fail? Has there been a breach to the vacuum seal or maybe a breakdown or materials within? There is little in between. If considering DC voltage,

2.4 Vacuum decay test or Pressure rise test...8 2.5 Tracer gas leak testing . defects in material, etc. A leak test procedure is usually a quality control step to assure device integrity, and should preferably be a one-time non-destructive test, without impact on the environment and operators.

an AC dielectric withstand test at 50 kV is performed.Test duration is one minute. 6. Wiring Insulation:The terminal block connections are given an over-potential test of 1500 volts AC to ground. 6.0 OPERATION 6.1 Closing In the open position, the magnetic actuator’s armature rests against the bottom plate in the

mechanical vacuum bottle braces. Figure 1 - 400 A Contactor Vacuum Bottle Description Each vacuum bottle (Figure 2 ) consists of two contacts that are enclosed in a ceramic housing: an upper contact that is mounted to a fixed shaft, and a lower contact that is mounted to a movable shaft. A stainless steel bellow helps the CYANIDE LEACH TEST PROCEDURE. Bottle Leach Procedure for Cyanidation. Be sure to use at least 500g, but 1000g per test is better. Be sure to use a big enough bottle. . At the end of the test, vacuum filter the final cyanide leach slurry through a Buchner funnel containing filter paper into a filter flask.2 test methods are presented in this video about leak testing for plastic containers in a vacuum chamber. You can identify the source of the problem and find. Table 1. Test connections for the DC overpotential test. Test connections for the DC overpotential test are given in Table 1 (right), which will provide a test of all possible leakage paths in the circuit breaker. Table 100.19 from ANSI/NETA MTS-2011 provides recommended test voltages for proof testing and field testing medium-voltage power circuit breakers and .

ter/density bottle test for kaolin clay and sand was 2.68 and. . Gs from pycnometer/density bottle, partially vacuum and. . Test procedure for deter-

Vacuum box testing is a non-destructive examination (NDE/NDT) used for locating welding leaks. A vacuum box and a compressor create a high or low-pressure vacuum and a detergent solution is applied to the test area. .The factory test of a vacuum interrupter includes a magnetron test to determine the vacuum pressure of the sealed unit and to monitor for defects prior to shipment. The interrupters are typically measured with the magnetron twice to determine if there is a defect causing leakage prior to shipment. After this, theThe method can be used to identify gross defects and micron leaks in pharmaceutical, medical device and food packaging. Vacuum decay leak testing is an approved ASTM F2338-09 standard test method and is a FDA .

PRESSURE VACUUM BREAKER 765 – Field Testing Procedure Equipment Required For Test: Sight Tube Test Kit (1" clear plastic Sight Tube about 40" long with appro-priate fittings to attach to Testcocks of Vacuum Breaker.) Purpose of Test: (see diagram) To test the Air Inlet and the Check Valves for proper performance. Test Air Inlet: The Air Inlet .

form of leak test for certain boundaries, as indicated by Footnote 3 of Table 1. 3.2 The definition of each test type is as follows: Hydrostatic Test: (Leak and Structural) A test wherein a space is filled with a liquid to a specified head. Hydropneumatic Test: (Leak and Structural) A test combining a hydrostatic test and an air test, wherein aThe test begins when a sample is placed in a closely fitting evacuation test chamber, which is equipped with an external vacuum source. The test chamber and test system dead space are then evacuated for a predetermined period, with the predetermined targeted vacuum level chosen for the test is predetermined based on the test sample type under .

Examination Procedures for Vacuum Test - Free download as Word Doc (.doc / .docx), PDF File (.pdf), Text File (.txt) or read online for free. This document provides procedures for vacuum box testing of welds to locate leaks. It outlines that the vacuum box method uses a soapy solution applied to welds under differential pressure to detect leaks through bubble formation. The presentation will describe the procedure for field-test data analysis and discuss how the laboratory bottle-test data correlate with field tests data, thus validating the new bottle-testing .1. Place a magnetic stir bar into the sample bottle. 2. Place the bottle onto a magnetic stirring unit. 3. Stir at sufficient speed to create a vortex. 4. Use a 20 mL volumetric pipette to remove sample from the bottle; choose a point that is mid-depth and midway between the bottle wall and the vortex to obtain a homogenous sample. 5.

In the international standards for medium (and high-) voltage circuit-breakers no distinction is made in test requirements between circuit breakers with different arc-quenching media, like SF/sub 6/, oil and vacuum. This has led to the necessity to formulate a few additional test-requirements and interpretations that are specific to vacuum circuit breakers (VCB) only. In .

View and Download GE PowerVac instructions manual online. Vacuum Circuit Breaker with ML-20 Mechanism. PowerVac circuit breakers pdf manual download.

As with almost every facet of vacuum systems, there is no single method which fulfils every situation and every criterion. This is certainly the case with leak detection, with four main methods being employed: the bubble test; pressure decay test; pressure rise test; and helium sniffer mode/helium vacuum mode tests.These four tests roughly correspond to the “simplistic” .

Place the sample (e.g., a bottle, can, or container) in the vacuum chamber. Ensure it is properly positioned and secured. Step 3: Initiate the Vacuum. Start the vacuum pump to reduce the pressure inside the chamber. The VLT-ST model allows you to set the desired vacuum level accurately. Step 4: Monitor for Leaks. Observe the sample and the .

vcb testing procedure in pdf

Remoting. By default the game that is being analyzed, PIX user interface, and PIX analysis engine all run on the same computer. It is also possible to run the PIX user interface on .

vacuum bottle test procedure pdf|vacuum bottle integrity testing